About Global Lift Used Forklifts Santa Clara

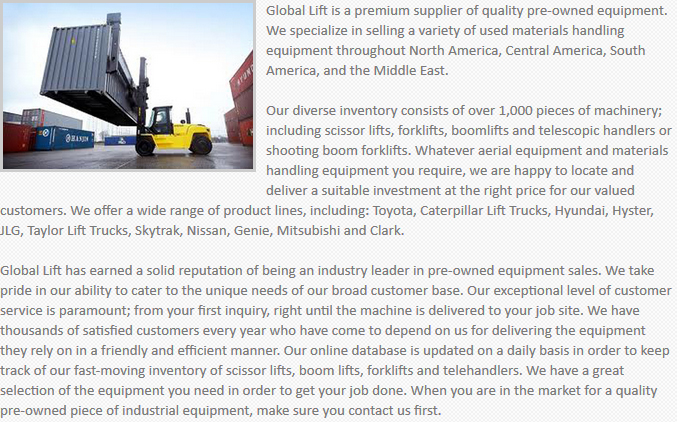

Global Lift Santa Clara - Buying a forklift is not to be taken lightly. A forklift is a large capital expense, and a complex machinery with a motor strong enough to perform heavy-lifting tasks. The price tag for a forklift ranges from ten thousand dollars to thirty thousand dollars, comparable to the cost of a small truck. If buying a used forklift, be certain to have it checked for potential mechanical problems.

The two types of forklift motors are: internal combustion or electric. Forklifts with electric motors are usually more pricey than those with internal combustion motors. The motor size must suit the kind of work for which the forklift will be used. A forklift with a big motor costs more compared to one with a smaller motor.

Motors which utilize propane or gasoline can lift heavier weights because they are normally stronger than electric motor. The downside is that gas motors tend to develop problems more often than electric motors. Depending on the price of propane or gas, gas powered forklifts can be more expensive to operate than electric powered forklifts.

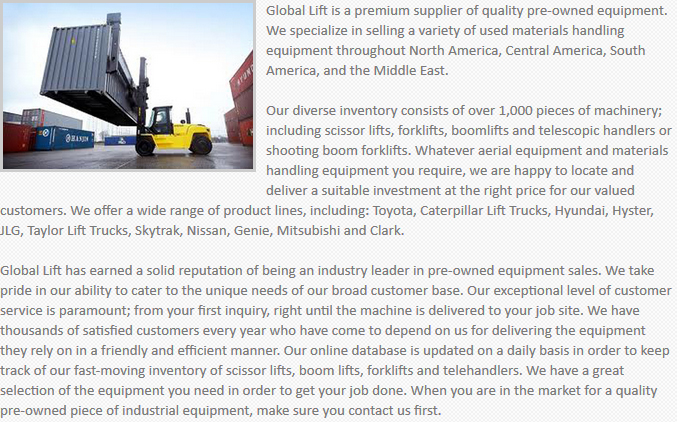

Some reputable manufacturers of forklifts are Mitsubishi Caterpillar, Crown Equipment Corp., Toyota Industries and NACCO Industries. Before making a decision, research the different manufacturers and the availability of parts. Testimonials, prices and reviews can be found on-line.

In the US, 20,000 individuals are hurt every year in accidents related to the utilization of forklifts. And each and every year about 100 deaths are attributed to forklift accidents. Luckily, proper training about maintenance and operation procedures can significantly reduce the chance of accidents. The following basic safety rules and suggestions should be followed when utilizing a forklift.

It is the job of the employer to make certain that the proper training program is provided to the employees and that operators of forklifts are qualified.. Training includes a combination of presentations, lectures, discussions and practical hands-on training. Reevaluation should take place every three years. Operators of forklifts need to be up-to-date with current forklift safety regulations. Forklift training program content covers dangers of forklift operations, general workplace hazards, workplace lighting and surfaces, and dangers connected to using the specific forklift that the worker will be utilizing. An employee should be eighteen years of age or over to operate a forklift.

In order to make sure that the machinery is functioning properly and safely, forklift inspection must be done every day. The inspection involves keeping a checklist of things and reporting any concerns at once.

Safe use of a forklift involves a clean and safe workplace. A safe work site means establishing "traffic lanes" which are designated for forklift use only. Warning systems like for example horns and flashing lights must be in place to indicate when there is an approaching forklift. Forklift docking stations must be inspected daily and kept in good repair.

Included in the general safety guidelines of utilizing a forklift are respecting the load capacity of the forklift and never exceeding the maximum; avoiding known hazards on the ground, such as wet spots or oil spills; making sure that there is enough clearance for the load; lowering or raising the load only when the forklift is stationary; and keeping arms, legs and hands in the vehicle during operation.

Powered lift trucks referred to as forklifts are used in almost every business to move heavy products and supplies. The forklift is a very durable and dependable equipment that has become important tools in a lot of warehouse and construction environments. Forklift models vary depending on the type of fuel that is utilized to power the lift truck and the type of work environment.

Electric forklifts are great for work sites which have limited ventilation since they produce no exhaust fumes and are fairly quiet. They are designed to be powered by industrial-strength, large batteries. Since the electric forklift batteries require charging, the worksite would need a charging station. The batteries are tough and could be re-charged up to one thousand five hundred times before they have to be replaced. The charging station must be located in a ventilated area and include an emergency eyewash station and an acid spill kit.

Liquid propane powered forklifts are frequently utilized in modern industrial operations because propane has several benefits over electric and diesel. Propane models are cleaner to operate than diesel-powered units. There is no down time needed to recharge an industrial battery, and the cost of electricity is more than the cost of propane. A forklift propane tank could be refueled quickly and easily by changing out the empty tank with a full tank. Typically an off-site supplier refills the empty tank, making refueling very efficient and safe.

For outdoor applications and rough terrain, the gas and diesel forklifts are the machinery of choice. These machines are fairly common in lumber yards and on construction sites. Their disadvantages include odorous exhaust, relatively high fuel costs and relatively high maintenance requirements. Their advantages include dependability in tough conditions and a longer lifespan compared to other units. Gasoline and diesel units should be refueled at a supply station on site that meets health and safety policies.

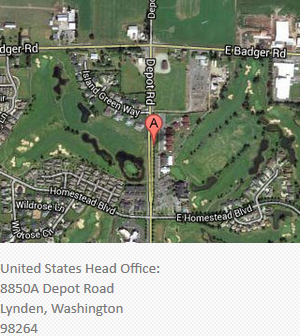

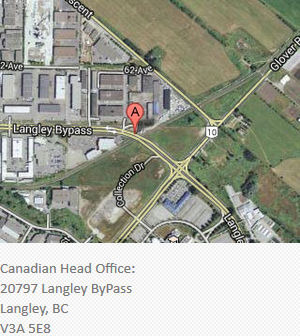

Contact Info

Questions or Comments